Recent News

- Second innoUP-Meeting in Leoben

- apromace’ presentation at the GIFA 2019 exhibition

- Being guest at the austrian foundry institute in Leoben

- VDG-Akademie: Practical seminar “Quality control of cast iron melts via thermal analysis”

- Large foundry technology meeting in Salzburg 2018″

- Visiting the large foundry technology meeting 2018 in Salzburg

- Der Nikolaus zu Besuch bei apromace

- Presentation for Barbara day 2017 in Leipzig

- Participation in the foundry conference „Foundry on Wheels“ in Agueda, Portugal

- Scientific exchange at the university of Porto, Portugal

Second innoUP-Meeting in Leoben

07. November 2019

This year, the apromace data systems GmbH took part with a guest lecture on ”Big Data Management und Thermische Analyse in Gießereien”. Furthermore, apromace offered the opportunity to take a look on the current foundry-MES-demonstration after the meeting.

apromace’ presentation at the GIFA 2019 exhibition

24th-29th of June, 2019

apromace was showing its novel developments at the GIFA 2019 exhibition in Düsseldorf. Consequentially, based on the successful cooperation with the Technical Service Kuehn GmbH (TSK), both companies had their presentation at a shared booth.

With our top level slogan “Foundry 4.1” we did match the GIFA visitors requests. Digitalization, that was classified only as “nice to have” at the last GIFA exhibition in 2015, now is a generally used term but even today acquiring data does not end in itself.

Combining our advanced foundry-specific MES-solution apromaceGUSS with distinct metallurgic expertise indicates the foundry sectors silver bullet to fullfill the continuously rising requirements of an extremly tense market. Today, the coexistence of several systems is still state of the art in the foundry sector.

With our thermal analysis apromaceTA with various unique features we provide the optimal link to bring together an extensive process data acquisition with a metallurgical control circuit.

Visitors at our booth experienced a closed to reality demonstation of a digitalized foundry on up to four displays showing the complex interlock of all acquired data to achieve perfect transparency. One highlight for the visitors at our booth was the manual refinement of the cast iron melt. Here, a small deviation from the automatically calculated proposal becomes immediately manifested in the metallurgical composition of all boxes which were poured with that particular melt which was directly illustrated in our real time melt list. Representing several employed customer solutions, the complexity of the demonstration turns out to be our unique selling point at the GIFA 2019 that lead to numerous concrete requests.

Traceability of process data starting from the article to the melt, sand or core charge, the possible integration of wireless temperature measuring lances with included acquisition of measuring time and the corresponding location as well as the requested expertise in the field of unique metallurgical problems were brought together to perfect the scope of services that enable both companies, apromace and TSK, to possess wholistic as well as future-proof solutions for complexe problems.

Being guest at the austrian foundry institute in Leoben

08th/09th of November, 2018

Dr. Rolf Fischer and Dr. Florian Hanzig from the TA-development team did visite the austrian foundry institute in Leoben to attend the first project meeting of the innoUp project “cast iron” where apromace data systems GmbH is taking part with its thermal analysis software apromaceTA.

At the first day three talks concerning the specific topics “topological optimization” and “energy flow optimization” did conclude the presentation of the first years achievements.

Retroperspectively, it has to be concluded that additional to the thermal analysis solution apromaceTA more tools from the apromace portfolio for example the foundry-MES apromaceGUSS as well as the energy monitoring system apromaceEMS would fit very well to the project aims and the requirements of the participating foundries.

The second day was dedicated to the installation of the thermal analysis solution apromaceTA and the following successful tests of the cast iron and aluminum group in comparison to the recent thermal analysis system at the ÖGI. Especially, the high quality of apromaceTA arise in combination with the recent realtime a/d-converter of the Technical Service Kuehn GmbH.

apromace Technical Service Kühn Austrian Foundry Institute (ÖGI)

VDG-Akademie: Practical seminar “Quality control of cast iron melts via thermal analysis”

03rd/04th of May, 2018

The apromace data systems GmbH, represented by Dr. Florian Hanzig, joined the VDG practical seminar “Quality control of cast iron melts via thermal analysis” in context of the VDG-Akademie at the technical university of Clausthal.

Initiated by two very successful demonstrations of the innovative and up to date package apromaceTA for thermal analysis of metal melts using Fe-C and Al-Cu alloys at the institute of metallurgy – department of foundry technology, the invitation to participate in the practical seminar “Quality control of cast iron melts via thermal analysis” in frame of the VDG-Akademie was carried out by Prof. Tonn.

At first Dr. Florian Hanzig introduced the participants with his talk “Basics of temperature measurement” to the aspects and the variety of measuring temperature. The following talk “Measuring temperature in thermal analysis – error sources and potential improvements” directed the attention to the expected error magnitudes using only standardized measurement equipment. Utilizing practical expamples from apromaceTA tests Dr. Florian Hanzig was able to demonstrate that the potential measurement error can by reduced by more than ninety percent.

Finally, the seminar was completed by a short but brilliant demonstration of consequences for the specific quality characteristics of metal melts using different inoculants by our partner Uwe Kühn based on the efficient combination of the thermal analysis software apromaceTA and the Technical Service Kuehn GmbHs manifold portfolio of thermal analysis sensors.

apromace Technical Service Kühn VDG-Akademie Gießereitechnik | TU Clausthal

Large foundry technology meeting in Salzburg 2018

26th/27th of April, 2018

With more than 800 participants and more than 30 scientific contributions related to the topics cast iron and cast steel, nonferrous metal casting as well as production technology the large foundry technology meeting 2018 in Salzburg offered the unique possibility to demonstrate and to discuss recent problems in a versatile manner.

Together with our partner Technical Service Kuehn GmbH the apromace data systems GmbH participates in the large foundry technology meeting 2018 as exhibitor. In a broad spectrum of displaying companies along the complete foundry technological value chain apromace data systems GmbH presented herself with the proven foundry-MES apromaceGUSS. Especially, both enterprises put the focus on an up to date combination of data from the thermal analysis of metallic melts and different process parameters as well as on the presentation of recently developed measurement technology.

One key aspect of the scientific exchange in the topic cast iron and cast steel, non-ferrous metal casting and production technology was the future digital foundry – an issue the apromace data systems GmbH had on its banner for almost ten years – when industry 4.0 was not even born.

In the contect of the center of competence transparent foundry Dr. René Brunsch and Dr. Florian Hanzig were able to extend their wide-ranging network to foundries and research institutions.

In a otherwise very well organized meeting one drop of bitternes sticks out: In a large number of talks it was pointed out that new materials and alloys will be the answer of europes foundry industry to future challanges but no one did highlight how to achieve the

decreasing metallurcigal tolerances within a secure process window. Here, the standards setting apromaceTA receive the strategic importance for the foundry, that want to ensure their competitive advantage by the metalurgical control of challanging metal melts.

Visiting the large foundry technology meeting 2018 in Salzburg

26th/27th of April, 2018

apromace data systems is representing the Foundry-MES apromaceGUSS on the large foundry technology meeting 2018 in Salzburg. Integrated into the context of the transparent foundry the exposure is completed by the energy-monitoring system apromaceEMS as well as the new and innovative solution for thermal analysis apromaceTA. We appreciate the support by our metallurgical and foundry technological partner from Technical Service Kuehn GmbH, who is giving an insight into his comprehensive selection of sensors and temperature measurement technique.

We look forward to your visit at our booth!

St. Nicholas did visit apromace

06th of December, 2017

On the 6th of Decembers early morning St. Nicholas did visite apromace data systems GmbH. Due to extensive and sophisticated preparations we were able to celebreate a fully loaded winter boot that was filled with:

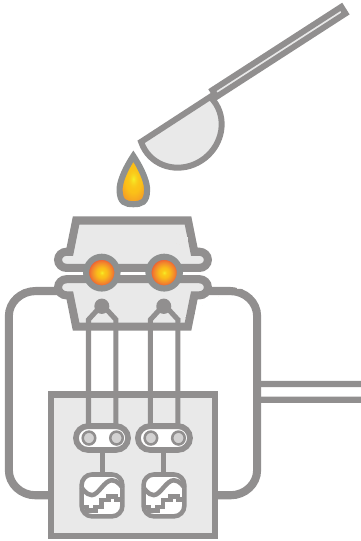

1. a versatile, high precision and intuitively operateble Softwaretool for the thermal analysis of metal melts

2. a modern analog digital converter with a sampling rate of up to 50 Hz

3. a thermal analysis sensor with maximum accuracy as well as

4. a large amount of candy for the apromace data systems GmbH team members.

If you are interested in extremly high process reliability concerning thermal analysis, in producing materials with outstanding high quality requirements and are you assume additional potential to optimize for example your charge makeup system, do ask for information and convince yourselve of the thermal analysis package apromaceTA performance that holds:

Detect MORE, respond FASTER, produce BETTER!

Presentation for Barbara day 2017 in Leipzig

25th of November, 2017

For this years Barbara day, organized by the federal association of the German foundry industry (BDG) and the association of German foundry specialists (VDG), Dr. René Brunsch from the apromace data systems GmbH held a talk about process-data driven optimization of the foundry on the basis of an industry 4.0 suitable thermal analysis

and successfully built a bridge between the challenge of specialized personnel and the topics of networking

and foundry 4.0

. With his energetic presentation he was able to convince the foundry managers and supervisors of the advantages the new alloy analysis tool apromaceTA brings with it.

Participation in the foundry conference Foundry on Wheels

in Agueda, Portugal

19th/20th of October, 2017

The participation in this years Foundry on Wheels conference (FoW 2017) enabled the apromace data systems GmbH to promote their extensive portfolio of process-optimization tools directly at the venue point between automotive and foundry industry. Starting with the established foundry-MES apromaceGUSS, the range has successfully been stretched from our innovative software solution for the thermal analysis of metal alloys, apromaceTA, up to our energy data management system apromaceEMS in order to present a holistic solution which conforms to both the highest quality- as well as sustainability standards.

Noteworthy was our visit at the new foundry for nodular iron SP21 by Sakthi Portugal, in which critical safety components are produced for the automotive industry. The insight into the, not just in terms of architecture, transparent foundry confirms the proven approach we took with apromaceGUSS, our foundryMES: process control along the complete production chain to ensure full transparency and traceability within the foundry.

Scientific exchange at the university of Porto, Portugal

18th of October, 2017

On the way to the foundry conference Foundry on Wheels 2017 in Agueda, Portugal (see above), Dr. René Brunsch and Dr. Florian Hanzig from the apromace data systems GmbH took the opportunity to visit Prof. Carlos Silva Ribeiro, who not only holds a remarkable reputation amongst researchers and professors in the fields of material science and foundry research, but also stands out because of his extreme proximity to the metal casting industry. His work at the institute of metallurgy and material-science (DEMM) within the faculty of engineering (FEUP) at the university of Porto gave us the unique opportunity to test the innovations of our versatile tool for the thermal analysis of metal alloys apromaceTA. Convinced by the sophisticated combination of metallurgical, IT-technical and metrological know-how, Prof. Carlos Silva Ribeiro was delighted to find that apromaceTA, regarding accuracy and resolving power, stands out in a remarkable way in the field of thermal analysis solutions and that it would be of great value for his institution, especially for the scientific work of his doctoral students.